75SCF-8-manufacture,factory,supplier from China

(Total 24 Products for 75SCF-8)

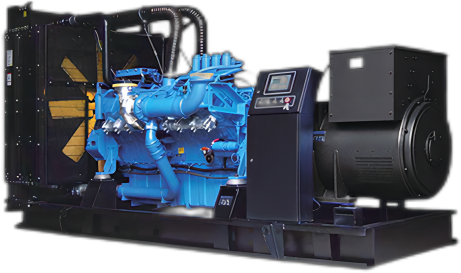

There is no unbalanced inertial force, it can operate smoothly at high speed, and can achieve foundationless operation.

Contact Now

Inverter starting avoids grid shocks, intelligent inverter air pressure control reduces energy-intensive run times, and precise constant voltage control maintains system pressure deviations within 0.1 bar. Every detail is greatly optimized on the whole system and pipeline, ensure its stability as well as reduce the energy consumption as much as possible90 SFe-890:90kW / Electric motor power S:Screw F:Air cool -8:8bar / Rated pressure 8bar e:Various frequency NO T:Single-stage compression 90 SFe-8ParameterElectric motor powerDischarge air volume FADWork pressure55-132 K

Contact Now

Optimized rotor structure air end, lower noise, higher efficiency, longer life. Integrated air intake system, effectively prevent lubricating oil spill, ensure low load start, reduce power consumption. Simple and accurate control system ensures safe operation.What is 15 SF-8 ?15:15kW / Electric motor power 15kW S: Screw F: Air cool -8:8bar / Rated pressure 8bar Have e:Power frequency No T: Single-stage compression15 SF-8 ParameterElectric motor powerDischarge air volume FADWork pressure7.5-37 kW1.0-6.1 m³

Contact Now

Stainless steel screw air end, stainless steel system, which can operate stably for a long time and maintain the efficiency after major maintenance. Integrated modular design, no complex pipelines and circuits, less failure points. Ergonomic structure design, simplify installation, more convenient maintenance, reduce maintenance costs.22 WSFe-822: Electric motor power 22kW W: water lubrication S:Screw F:Air cool -8:Rated pressure 8bar e:Various frequency no T:单级压缩 / Single-stage compression 22 WSFe-8ParameterElectric motor powerDischarge air v

Contact Now

Integrated air intake system, effectively prevent lubricating oil spill, ensure low load start, reduce power consumption.Simple and accurate control system ensures safe operation of the equipment. The air compressor and motor are designed with low center of gravity to reduce noise and vibration. 75 SF-8 75:75kW / Electric motor power 75kW S:Screw F: Air cool -8:8bar / Rated pressure 8bar DO NOT HAVE e:Power frequency DO NOT HAVE T:Single-stage compression 75 SF-8ParameterElectric motor powerDischarge air volume FADWork pressure55-132 KW9.6-23.2 m³/min8 barModelEle

Contact Now

High efficient separator maintains extreme oil content control ability under all operating pressures to protect the environment.22 SOe-822:Electric motor power 22kW S: Screw O: Oil cooling -8: Rated pressure 8bar e:Various frequency NO T:Single-stage compression 22 SOe-8ParameterElectric motor powerDischarge air volume FADWork pressure7.5-75 kW0.4-13.1 m³/min8 barModelElectricmotor powerAir dischargecapacity FADRatedSpeedWeightDimensions(LxWxH)Air dischargevalve size7.5SOe-87.5 kW0.4-1.15 m³/min3600 RPM160 kg930×680×880 &n

Contact Now

There is no unbalanced inertial force, it can operate smoothly at high speed, and can achieve foundationless operation.

Contact Now

Dual-mode frequency conversion integrated control simplifies circuits, increases the control accuracy of the cooling fan, and enables the air compressor to work smoothly in various ambient temperature environments. The air intake system adopts heavy load air filter, the unique design of the intake box can filter the dust particles in the air more effectively, ensure the intake quality and extend the service life of the air compressor.132 SFeT-8132:Electric motor power 132kWS:Screw F:Air cool -8:Rated pressure 8bar e:Various frequency T:Two-stage compression 132 SFeT-8ParameterEl

Contact Now

The degree of automation is high, and the operator does not need to undergo long-term training, and unattended operation can be achieved. It has the characteristics of forced gas transmission, and the volume flow is almost unaffected by the exhaust pressure, and it can maintain high efficiency in a wide range of speeds.ParametersModelRatedFADMotorPowerRatedPressureAirEndMotorProtectionClassWeightDimensions (LxWxH)90SCFT-820 m³/min90 kW8 barTwoStageCompressionIP542,185 kg2,825×1,525×1,620 mm110SCFT-823 m³/min110 kW2.490 kg2,965×1,525×1,740 mm132SCFT-827&

Contact Now

IntroductionAir compressors are widely used in highway, railway, mining, water conservancy, shipbuilding,urban construction, energy, military and other industries.ParametersModel75SDY-890SDY-890SDY-14.5Air EndSingle Stage CompressionType4 wheelMotor Protection ClassIP54Rated Pressure8 bar8 bar14.5 barRated FAD13.2 m3/mir15.5 m³/min13 m³/minMotor Power75 kW90 kW90 kWWeight2,020 kg2,125 kg2,120 kgDimensions (LxWxH)3,050×1,620×2,090 mmCompany:The company lies in rencheng city shandong jining province ,with workshop space of 1000 m2 and more th

Contact Now

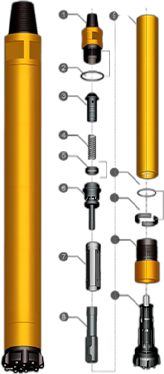

PartsWeight /kgPartsWeight /kg1Top Sub 8.8 Kg9External Cylinder15.9 Kg2"O"Ring 0.01 Kg10Stop Ring0.2 Kg3Check Valve 0.46 Kg11"O"Ring0.01 Kg4Spring 0.04 Kg12Drive Chuck3.7 Kg5rubber Buffer 0.2 Kg13Drill Bit6Valve Sea 2.1 Kg7InternalCylinder 2.45 Kg8Piston 9 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1032mm43Kg99mm API2 3/8"REG DHD340110-135mmWorking PressureRecommended Rotation SpeedAir Consumption1.0Mpa1.8 Mpa1.0-2.2 Mpa 30-60 r/min

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub14.7 Kg9 Piston Case23.5 Kg2 "O"Ring0.02 Kg10 Retainer Ring0.5 Kg3 Check Valve1 Kg11 "O"Ring0.01 Kg4 Spring0.06 Kg12 Drive Chuck7.8 Kg5 Rubber Buffer0.2 Kg13 Drill Bit6 Valve Sea4.1 Kg7 Inner Cylinder4.4 Kg8 Piston17.3 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1178mm73.6Kg125mm API2 3/8"REG SD5135-155mmWorking PressureRecommended Rotation SpeedAir Consumption1.8 Mpa2.4Mpa1.0-2.5Mpa30-60 r

Contact Now

Inverter starting avoids grid shocks, intelligent inverter air pressure control reduces energy-intensive run times, and precise constant voltage control maintains system pressure deviations within 0.1 bar.WHY CHOOSE US -1. We have many years of production and management experience2. We have our own professional testing equipment3. We can provide OEM&ODM custom services4. Provide complete solution for our clients5. Packaging and transportation professional designer team37 SFe-8ParameterElectric motor powerDischarge air volume

Contact Now

PartsWeight /kgPartsWeight /kg1Top Sub 160 Kg9Piston Case317 Kg2Adjuster Shim 1.5 Kg10Guided Sleeve43.5 Kg3O'Ring0.05 Kg11Check Ring0.5 Kg4Check Valve3.4 Kg12Retainer Ring12.4 Kg5Spring0.4 Kg13O'Ring0.03 Kg6Valve Seat31.5 Kg14Adjuster Shim1.9 Kg7Inner Cylinder28.7 Kg15Drive Chuck77.4 Kg8Piston173 Kg16Drill BitTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1861mm 851Kg332mm API7 5/8"REG SP330350-550mmWorking PressureRecommended Rotation SpeedAir Consumption1.8 Mpa

Contact Now

PartsWeight /kgPart No1Top Sub16001-SP1480-012Adjuster Shim1.501-SP1480-023O'Ring0.0501-SP1480-034Check Valve3.401-SP1480-045Spring0.0401-SP1480-056Valve Seat 31.501-SP1480-067Inner Cylinder28.701-SP1480-078Piston17301-SP1480-089Piston Case29201-SP1480-0910Guided Sleeve31.501-SP1480-1011Check Ring0.501-SP1480-1112Retainer Ring7.601-SP1480-1213O'Ring0.0301-SP1480-1314Adjuster Shim1.501-SP1480-1415Drive Chuck6401-SP1480-1516Drill Bit01-SP1480-16Technical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1744mm 796kg332mm API7 5/8"

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub14.7 Kg9 Piston Case24.7 Kg2 "O"Ring 0.02 Kg10 Guided Sleeve1 Kg3 Check Valve1 Kg11 Retainer Ring0.6 Kg4 Spring0.06 Kg12 "O"Ring0.01 Kg5 Rubber Buffer 0.2 Kg13 Drive Chuc5.6 Kg6 Valve Sea 4.1 Kg14 Drill Bit7 Inner Cylinder 4.4 Kg8 Piston17 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1154mm 73.5Kg126mm API2 3/8"REGQL50135-155mmWorking PressureRecommended Rotation Spe

Contact Now

PartsWeight /kgPart No1Top Sub1401-ND55A-012O'Ring0.0101-ND55A-023Check Valve0.601-ND55A-034Spring0.0601-ND55A-045Valve Seat 2.1501-ND55A-056Inner Cylinder3.301-ND55A-067Piston15.501-ND55A-078Piston Case24.201-ND55A-089Guided Sleeve2.6401-ND55A-0910Retainer Ring0.501-ND55A-1011O'Ring0.0101-ND55A-1112Drive Chuck701-ND55A-1213Drill Bit01-ND55A-13Technical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1122mm 70Kg126mm API2 3/8"REG ND55A136-155mmWorking PressureRecommended Rotation SpeedAir Consumption1.0

Contact Now

PartsWeight /kgPart No1Top Sub4.501-ND35A-012O'Ring0.0101-ND35A-023Check Valve0.1301-ND35A-034Spring0.0201-ND35A-045Valve Seat 0.7601-ND35A-056Inner Cylinder1.4501-ND35A-067Piston4.801-ND35A-078Piston Case9.501-ND35A-089Guided Sleeve0.901-ND35A-0910Retainer Ring0.1501-ND35A-1011O'Ring0.0101-ND35A-1112Drive Chuck1.901-ND35A-1213Drill Bit01-ND35A-13Technical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range886mm24.2kg482mmAPI2 3/8"REG ND35A90-115mmWorking PressureRecommended Rotation SpeedAir Consumption1.0 Mpa

Contact Now

PartsWeight /kgPart No1Top Sub7.401-SP480-012O'Ring0.0101-SP480-023Check Valve0.301-SP480-034Spring0.0401-SP480-045Valve Seat 101-SP480-056Inner Cylinder1.501-SP480-067Piston801-SP480-078Piston Case11.601-SP480-089Guided Sleeve1.501-SP480-0910Check Ring0.0201-SP480-1011Retainer Ring0.3401-SP480-1112Drive Chuck3.101-SP480-1213Drill Bit01-SP480-13Technical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range863mm 35kg100mm API2 3/8"REGSP480 108-135mmWorking PressureRecommended Rotation SpeedAir Consumption1.0Mpa1.8Mpa1.0-1.9 Mpa30-

Contact Now

PartsWeight /kgPartsWeight /kg1Top Sub14 Kg9Guided Sleeve2.75 Kg2O'Ring 0.01 Kg10Retainer Ring0.45 Kg3Check Valve0.6 Kg11O'Ring0.01 Kg4Spring 0.06 Kg12Drive Chuck5.4 Kg5Valve Seat 2.15 Kg13Drill Bit6Inner Cylinder3.3 Kg7Piston 15.5 Kg8Piston Case 24.2 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1102mm68.5Kg 126mmAPI2 3/8"REG QL50A136-155mmWorking PressureRecommended Rotation SpeedAir Consumption1.0 Mpa1.8 Mpa1.0-2.5 Mpa 30-60 r/min 7 m³/min13 m³/minCom

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub13.7 Kg 9 Guided Sleeve2.6 Kg2 "O"Ring 0.02 Kg 10 Retainer Ring0.7 Kg3 Check Valve0.7 Kg 11 "O"Ring0.01 Kg4 Spring0.1 Kg 12 Drive Chuck7.1 Kg5 Valve Seat2 Kg 13 Drill Bit6 Inner Cylinder2.8 Kg7 Piston15 Kg8 Piston Case24 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1122mm 70.5Kg126mm API 2 3/8"REG M50136-155 mmWorking PressureRecommended Rotation SpeedAir C

Contact Now

PartsWeight /kgPart No1Top Sub8.101-ND45A-012O'Ring0.0101-ND45A-023Check Valve0.301-ND45A-034Spring0.0401-ND45A-045Valve Seat 1.501-ND45A-056Inner Cylinder2.101-ND45A-067Piston8.401-ND45A-078Piston Case1501-ND45A-089Guided Sleeve101-ND45A-0910Retainer Ring0.201-ND45A-1011O'Ring0.0101-ND45A-1112Drive Chuck3.601-ND45A-1213Drill Bit01-ND45A-13Technical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range986mm40.5Kg99mmAPI2 3/8"REG ND45A100-135mmWorking PressureRecommended Rotation SpeedAir Consumption1.0 Mpa1.8 Mpa

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub12.7 Kg 9 Guided Sleeve3 Kg2 "O"Ring0.01 Kg 10 Retainer Ring0.7 Kg3 Check Valve0.6 Kg 11 "O"Ring0.01 Kg4 Spring0.06 Kg 12 Drive Chuck5.3 Kg5 Valve Seat1.7 Kg 13 Drill Bit6 Inner Cylinder2.9 Kg7 Piston12 Kg8 Piston Case23 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1080mm 62Kg114mm API2 3/8"REGNM5C 125-146 mmWorking PressureRecommended Rotation SpeedAir Consumption1.

Contact Now

PartsWeight /kgPartsWeight /kg1Top Sub 8.89 Piston Case16.52"O"Ring0.0110 Cuided Sleeve0.93Check Valve0.4611 Retainer Ring0.24Spring0.0412 "O"Ring0.015Rubber Buffer0.213 Driver Chuck3.36Valve Seat2.114 Drill Bit7 Inner Cylinder2.458 Piston8.8Technical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1102mm43.7Kg99mm API2 3/8"REGQL40110-135 mmWorking PressureRecommended Rotation SpeedAir Consumption1.0 Mpa1.8 Mpa1.5-2.2 Mpa30-60 r/min 5.5 m³/min10 m³/minCompanyOur c

Contact Now

Relate News

Zoucheng Jusheng Mining Machinery Co., Ltd. (Shandong) was established in 2 0 1 8. The company's annual sales are more than 1 5 million US dollars. Before the establishment of the company, we have 1 5 years of experience in equipment sales and service. As one of the excellent authorized agents of ZEGA brand mining machinery, we supply ZEGA brand mining rigs and air compressors to global customers. At present, JS Drill has reached long-term cooperation with customers in more than 5 0 countries around the world.

1. What is your terms of delivery?EXW, FOB, CFR, CIF.We have a very good cooperation in shipping logistics, and the price is low.Not only our product price is advantageous, but also our logistics price. 2. How about your delivery time?Generally, it will take 7-10 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. We have the goods in stock and they will be shipped from the factory within three days.

Drilling rig is a complex machine, which consists of machines, units and mechanisms. A drilling rig is a mechanical device that drives drilling tools to drill underground to obtain physical geological data during exploration or development of mineral resources (including solid minerals, liquid minerals, gas minerals, etc.). Also called drilling machine. The main function is to drive the drilling tool to break the rock at the bottom of the hole, and to lower or lift the drilling tool in the hole. It can be used to drill rock cores, ore cores, cuttings, gaseous samples, liquid samples, etc.

If you need a drill rig for various purposes such as drilling a well to obtain natural resources (water, oil, geothermal energy, etc.) building a foundation, drilling holes in a mine, taking samples from the ground.It is necessary to first determine the purpose of the drilling rig and what kind of terrain it will mainly operate on. Depending on the terrain, you can choose different types of drilling rigs: rotary drilling rigs, impact drilling rigs, down-the-hole drilling rigs, top hammer drilling rigs (with high hammer), etc.

A customer from Puerto Rico in the United States asked our company to customize a 200-meter crawler water well drilling rig with diesel power generation/61kw.First, we will draw a rough model according to the customer's requirements, and then the designer will make a prototype based on the graphics. Now it has been made for the customer.

1. What is the warranty of our machine?Our main machine enjoys a 1 year warranty(except for the hammer), during this time all accessories broken can be changed for a new one.And we provide videos for machine install and operation.2. What is your terms of packing?Generally, we use standard exported wooden case for LCL goods, and fixed well for FCL goods.

The factory has become busy recently. As the number of customers gradually increases, so do the orders. However, we will still strictly control product quality so that customers can rest assured. The service quality will also increase accordingly.

Visiting a construction site abroad1 Visiting processSafety training:Before entering the construction site, I received a safety training. The training content may include safety regulations of the construction site, emergency response measures, correct use of personal protective equipment, etc.Listen carefully to the safety training, comply with the safety regulations of the construction site, and ensure your own safety.2 Site tour:The site staff will lead the tour.

For the construction machinery industry, its development mainly has the following three characteristics:1. Industry development is closely related to national macroeconomic developmentFor the construction machinery industry, the development of the industry is closely related to the development of downstream demand markets. The development of downstream industries such as the real estate industry, infrastructure industry, power industry, and coal industry has a high impact on the growth of demand for various types of construction machinery and equipment. Relevance.

What is your terms of payment? T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.