Drill Down The Hole Bit-manufacture,factory,supplier from China

(Total 24 Products for Drill Down The Hole Bit)

ProductProduct Parameters: Hole Depth 30 m Drill Pipe Sizes φ76×3,000 mm Hole Dia φ110-138 mm Hammer 4”/5" Rotation Torque(Max.) 3,200 N.m Rotation Speed 0-100 rpm Working Pressure 0.7-2.5 Mpa Length of Feed Beam 5,645 mm Feed Travel Length 3,660 mm Feed Extension 960 mm Feed Speed 26 m/min Feed Force 20 kN Pull Up Force 45 kN Feed Type Chain &

Contact Now

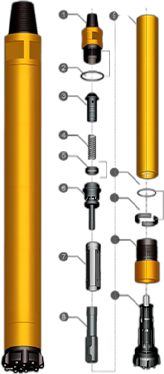

Product Description:As one of the important components of the entire down-the-hole drilling tool, the down-the-hole impactor is a working device of the down-the-hole drilling rig. The down-the-hole impactor is divided into low-wind pressure down-the-hole impactor, medium-pressure down-the-hole impactor and high-wind pressure down-the-hole impactor. Impactor.It can convert air pressure into impact energy, and simultaneously transfer impact energy and rotational force to the down-the-hole drill bit. The drill bit has fast drilling speed and low air consumption.

Contact Now

The impactor of a down-the-hole drill is a key component of the drilling process of a down-the-hole drill. It is used to provide axial reciprocating rock-breaking impact force to the drill bit in order to cool the drill bit and carry rock cuttings, etc. It is also the power fluid of the bottom hole power drill tool.Working principle of the impactor of a down-the-hole drill:The compressed gas enters the impactor through the drill pipe and is then discharged from the drill bit.

Contact Now

Product Description:As one of the important components of the entire down-the-hole drilling tool, the down-the-hole impactor is a working device of the down-the-hole drilling rig. The down-the-hole impactor is divided into low-wind pressure down-the-hole impactor, medium-pressure down-the-hole impactor and high-wind pressure down-the-hole impactor. Impactor.It can convert air pressure into impact energy, and simultaneously transfer impact energy and rotational force to the down-the-hole drill bit. The drill bit has fast drilling speed and low air consumption.

Contact Now

Product Desctiption:As one of the important components of the entire down-the-hole drilling tool, the down-the-hole impactor is a working device of the down-the-hole drilling rig. The down-the-hole impactor is divided into low-wind pressure down-the-hole impactor, medium-pressure down-the-hole impactor and high-wind pressure down-the-hole impactor. It can convert air pressure into impact energy, and simultaneously transfer impact energy and rotational force tothe down-the-hole drill bit.

Contact Now

1. Bit without foot valve will avoid the problem of foot valve broken or thermal expansion2.

Contact Now

Working principle of down-the-hole drilling rig impactor:The compressed gas enters the impactor through the drill pipe, and is then discharged from the drill bit. The discharged exhaust gas is used to discharge ballast.

Contact Now

Performance characteristics of the impactor of the down-the-hole drill:1.

Contact Now

Working principle of down-the-hole drilling rig impactor:The compressed gas enters the impactor through the drill pipe, and is then discharged from the drill bit. The discharged exhaust gas is used to discharge ballast.

Contact Now

Description:The impactor of a down-the-hole drilling rig is a key component of down-the-hole drilling rig drilling. It is used to provide axial reciprocating rock-breaking impact force to the drill bit in order to cool the drill bit and entrain cuttings. It is also the power fluid for downhole power drilling tools.

Contact Now

Advantage For such projects as the drill bit break, retrieving difficultly, we specially designed a safe and reliable anti-shedding device for the bit.PartsWeight /kgPartsWeight /kg1 Top Sub134 kg9 Piston Case220 kg2 Adjuster Shim0.8 kg10 Retainer Ring5.2 kg3 "O"Ring0.04 kg11 "O"Ring0.03 kg4 Check Valve1.5 kg12 Guided Sleeve5.2 kg5 Spring0.2 kg13 Adjuster Shim0.8 kg6 Valve Seat21 kg14 Drive Chuck53.5 kg7 Inner Cylinder29 kg15 Drill Bit8Piston118 kgTechnical parametersLength(Less bit)Weight Outer

Contact Now

Working principle of down-the-hole drilling rig impactor:The rotary motion of the impactor is provided by the rotary head, and the shaft thrust is provided by the propeller and transmitted to the impactor through the drill rod. The card sleeve is mainly used to transmit propulsion force and rotational motion to the drill bit.

Contact Now

Equipped with Yuchai YC6J220 power pack 12/15m³/min Air compressor for hole diameter φ90-115mm and with dry dust collector.JS421 Integrated DTH Surface drill rig with single power pack(only one diesel engine)to drive both screw air compressor and hydraulic system,compared with separated drill rigs,the fuel consumption reduced by 35%and maintenance cost down by 50%.Product Parameters:PowerYuchai YC6J220162 kWHole Depth 20 mDrill Pipe Sizes φ60 mm×3,000 mmHole Dia φ90-115mmDTH Hammer 3.5"RotationTorque(Max.) 1,258 N.mR

Contact Now

SP35AButton qty.pcs*dia.mmWeight(Kg)Head shapeHead Diameter (mm)Shank LengthSplinePort holesButton Type (Optional)Gauge ButtonsFront ButtonsFlat Face90 150 6 2 Domed+Ballistic6*Φ145*Φ124.3 Flat Face95 150 6 2 Domed+Ballistic6*Φ145*Φ124.4 Flat Face100 150 6 2 Domed+Ballistic6*Φ146*Φ124.6 Flat Face108 150 6 2 Domed+Ballistic8*Φ136*Φ124.9 CompanyJS DRILL is a large-scale professional manufacturer of high, medium and low wind pressure down-the-hole drilling rigs and water well drilling ri

Contact Now

Application For mininig,quarry blasting hole borehole drillingFor water well,depep hole well,oil and gas open hole drillingFor foundation and piling drillingPartsWeight /kgPartsWeight /kg1 Top Sub60 kg9 Retainer Ring 2.76 kg2 "O"Ring0.03 kg10 "O"Ring 0.02 kg3 Check Valve1.5 kg11 Guided Sleeve 5 kg4 Spring0.2 kg12 Drive Chuck 21 kg5 Valve Seat12.8 kg13 Drill Bitk6 Inner Cylinder13.5 kg7 Piston71 kg8Piston Case85 kgTechnical parametersLength(Less bit)Weight Outer diameterConnection

Contact Now

The use of a wide range:the bit is suitable for carbonate rock, limestone, chalk, clay rock,siltstone, sandstone and other soft and hard。

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub13.7 Kg 9 Guided Sleeve2.6 Kg2 "O"Ring 0.02 Kg 10 Retainer Ring0.7 Kg3 Check Valve0.7 Kg 11 "O"Ring0.01 Kg4 Spring0.1 Kg 12 Drive Chuck7.1 Kg5 Valve Seat2 Kg 13 Drill Bit6 Inner Cylinder2.8 Kg7 Piston15 Kg8 Piston Case24 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1122mm 70.5Kg126mm API 2 3/8"REG M50136-155 mmWorking PressureRecommended Rotation SpeedAir C

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub1.92 kg9 Guided Sleeve0.29 kg2 "O"Ring0.01 Kg10 Check Ring0.1 kg3 Check Valve0.08 kg11 Retainer Ring0.08 kg4 Spring0.01 Kg12 "O"Ring0.01 Kg5 Valve Seat0.46 kg13 Drive Chuck0.82 kg6 Inner Cylinder0.38 kg14 Drill Bit7 Piston1.16 kg8Piston Case3.46 kgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range698mm 8.8Kg56mm RD40 BOX BR1 64-76mmWorking PressureRecommended Rotation

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub14.7 Kg9 Piston Case23.5 Kg2 "O"Ring0.02 Kg10 Retainer Ring0.5 Kg3 Check Valve1 Kg11 "O"Ring0.01 Kg4 Spring0.06 Kg12 Drive Chuck7.8 Kg5 Rubber Buffer0.2 Kg13 Drill Bit6 Valve Sea4.1 Kg7 Inner Cylinder4.4 Kg8 Piston17.3 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1178mm73.6Kg125mm API2 3/8"REG SD5135-155mmWorking PressureRecommended Rotation SpeedAir Consumption1.8 Mpa2.4Mpa1.0-2.5Mpa30-60 r

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub2.5 Kg9 Guided Sleeve0.52 Kg2 "O"Ring0.01 Kg10 Retainer Ring0.1 Kg3 Check Valve0.08 Kg11 "O"Ring0.01 Kg4 Spring0.05 Kg12 Drive Chuck1.2 Kg5 Valve Seat0.5 Kg13 Drill Bit6 Inner Cylinder0.6 Kg7 Piston2.3 Kg8 Piston Case4.5 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range810mm 12.5Kg64mm RD50 BOX BR2 70-90mmWorking PressureRecommended Rotation SpeedAir Consumption1.0 Mpa1.4Mpa0.8

Contact Now

Each bit is made from quality alloy steel, and has been precision machined to produce a perfect body, heat treated to the required hardness, given surface compression for fatigue resistance.

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub12.7 Kg 9 Guided Sleeve3 Kg2 "O"Ring0.01 Kg 10 Retainer Ring0.7 Kg3 Check Valve0.6 Kg 11 "O"Ring0.01 Kg4 Spring0.06 Kg 12 Drive Chuck5.3 Kg5 Valve Seat1.7 Kg 13 Drill Bit6 Inner Cylinder2.9 Kg7 Piston12 Kg8 Piston Case23 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1080mm 62Kg114mm API2 3/8"REGNM5C 125-146 mmWorking PressureRecommended Rotation SpeedAir Consumption1.

Contact Now

Our Drill Bit is designed for professionals seeking exceptional structural optimization, strength, and ease of operation.

Contact Now

PartsWeight /kgPartsWeight /kg1 Top Sub20.3 Kg9 Piston Case37.2 Kg2 "O"Ring0.02 Kg10 Guided Sleeve2.5 Kg3 Check Valve0.8 Kg11 Retainer Ring0.6 Kg4 Spring0.05 Kg12 "O"Ring0.02 Kg5 Rubber Buffer0.3 Kg13 Drive Chuck6 Kg6 Inner Cylinder5 Kg14 Drill Bit7 Piston4 Kg8 Piston Case23.5 KgTechnical parametersLength(Less bit)Weight Outer diameterConnection ThreadBit ShankHole Range1063mm100.5Kg 142mmAPI3 1/2"REG DHD360150-190mmWorking PressureRecommended Rotati

Contact Now

Relate News

If you need a drill rig for various purposes such as drilling a well to obtain natural resources (water, oil, geothermal energy, etc.) building a foundation, drilling holes in a mine, taking samples from the ground.It is necessary to first determine the purpose of the drilling rig and what kind of terrain it will mainly operate on. Depending on the terrain, you can choose different types of drilling rigs: rotary drilling rigs, impact drilling rigs, down-the-hole drilling rigs, top hammer drilling rigs (with high hammer), etc.

Drilling rig is a complex machine, which consists of machines, units and mechanisms. A drilling rig is a mechanical device that drives drilling tools to drill underground to obtain physical geological data during exploration or development of mineral resources (including solid minerals, liquid minerals, gas minerals, etc.). Also called drilling machine. The main function is to drive the drilling tool to break the rock at the bottom of the hole, and to lower or lift the drilling tool in the hole. It can be used to drill rock cores, ore cores, cuttings, gaseous samples, liquid samples, etc.

Zoucheng Jusheng Mining Machinery Co., Ltd. (Shandong) was established in 2 0 1 8. The company's annual sales are more than 1 5 million US dollars. Before the establishment of the company, we have 1 5 years of experience in equipment sales and service. As one of the excellent authorized agents of ZEGA brand mining machinery, we supply ZEGA brand mining rigs and air compressors to global customers. At present, JS Drill has reached long-term cooperation with customers in more than 5 0 countries around the world.

For the construction machinery industry, its development mainly has the following three characteristics:1. Industry development is closely related to national macroeconomic developmentFor the construction machinery industry, the development of the industry is closely related to the development of downstream demand markets. The development of downstream industries such as the real estate industry, infrastructure industry, power industry, and coal industry has a high impact on the growth of demand for various types of construction machinery and equipment. Relevance.

Visiting a construction site abroad1 Visiting processSafety training:Before entering the construction site, I received a safety training. The training content may include safety regulations of the construction site, emergency response measures, correct use of personal protective equipment, etc.Listen carefully to the safety training, comply with the safety regulations of the construction site, and ensure your own safety.2 Site tour:The site staff will lead the tour.

The factory has become busy recently. As the number of customers gradually increases, so do the orders. However, we will still strictly control product quality so that customers can rest assured. The service quality will also increase accordingly.

A customer from Puerto Rico in the United States asked our company to customize a 200-meter crawler water well drilling rig with diesel power generation/61kw.First, we will draw a rough model according to the customer's requirements, and then the designer will make a prototype based on the graphics. Now it has been made for the customer.

1. What is your terms of delivery?EXW, FOB, CFR, CIF.We have a very good cooperation in shipping logistics, and the price is low.Not only our product price is advantageous, but also our logistics price. 2. How about your delivery time?Generally, it will take 7-10 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. We have the goods in stock and they will be shipped from the factory within three days.

What is your terms of payment? T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

1. What is the warranty of our machine?Our main machine enjoys a 1 year warranty(except for the hammer), during this time all accessories broken can be changed for a new one.And we provide videos for machine install and operation.2. What is your terms of packing?Generally, we use standard exported wooden case for LCL goods, and fixed well for FCL goods.