The impactor of a down-the-hole drill is a key component of the drilling process of a down-the-hole drill.

It is used to provide axial reciprocating rock-breaking impact force to the drill bit in order to cool the drill bit and carry rock cuttings, etc.

It is also the power fluid of the bottom hole power drill tool.

Working principle of the impactor of a down-the-hole drill:

The compressed gas enters the impactor through the drill pipe and is then discharged from the drill bit. The discharged exhaust gas is used to remove the rock.

The rotary motion of the impactor is provided by the rotary head, and the axial thrust is provided by the propeller,

which is transmitted to the impactor through the drill rod. The drill sleeve is mainly used to transmit propulsion force and rotary motion to the drill bit.

The retaining ring controls the axial movement of the drill bit, and the check valve is used to prevent debris such as rock chips from entering

the impactor when the compressed air supply is stopped. During the drilling process, the drill bit is pushed into the impactor and pressed on the drill sleeve.

At this time, the piston directly impacts the drill bit for rock drilling. When the drill bit is lifted off the bottom of the hole, strong blowing begins.

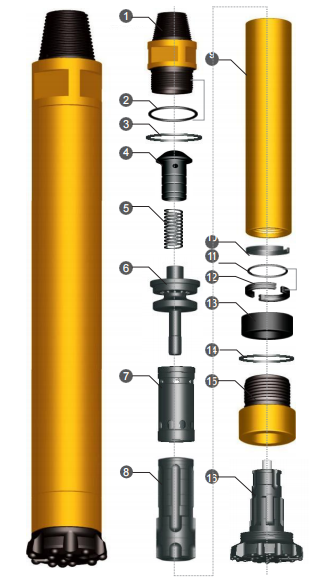

| Parts Description | Weight/Kg | Part Number |

1 | Top Sub | 70.0 | CSD12-01 |

2 | O-Ring of Top Sub | 0.04 | CSD12-02 |

3 | Breakout Ring of Top Sub | 0.80 | CSD12-03 |

4 | Check Valve | 3.00 | CSD12-04 |

5 | Spring | 0.10 | CSD12-05 |

6 | Air Distributor | 20.00 | CSD12-06 |

7 | Internal Cylinder | 23.0 | CSD12-07 |

8 | Piston | 125.00 | CSD12-08 |

9 | External Cylinder | 170.0 | CSD12-09 |

10 | Piston Retaining Ring | 1.50 | CSD12-10 |

11 | O-Ring of Stop Ring | 0.04 | CSD12-11 |

12 | Stop Ring | 4.80 | CSD12-12 |

13 | Guided Sleeve | 18.0 | CSD12-13 |

14 | Breakout ring of Drive Chuck | 0.80 | CSD12-14 |

15 | Drive Chuck | 51.0 | CSD12-15 |

16 | Drill Bit |

| CSD12-16 |

Parameters |

|

|

|

|

|

Length(Without bits) | Weigth(without bit) | External diameter | Bit Shank | Hole range | Connection Thread |

1880mm | 487.00 kg | Φ275 mm | SD12

CSD12 | Φ305-Φ445 | API 6 5/8" Reg |

Working Pressure | impact rate at 1.7 Mpa | Recommended rotaion speed | Air consumpson

|

|

|

| 1.0Mpa | 1.8Mpa

| 2.4Mpa |

1.0-2.5Mpa | 16 HZ | 15-25 r/min | 30 m³/min | 56 m³/min | 78 m³/min |

Company:

![Company Company]()

We has been for a long term focus on "drilling industry" solutions and research. The company recruits mining industry elite, grasping the core technology with a number of R & D patents. JuSheng people always insist on "change" mode, making bold innovation. It is being a top manufacturing company with a full system of research, manufacture and marketing.

"New step, new journey" JuSheng takes a journey full of glory. The JuSheng people devote themselves into the "human drilling tools industry" with the most responsible and most loving heart. The company will strive to improve in product cost performance, recognition ratio and comprehensive ratio, committed to the company into best intellectual property value, the most innovative ability, the most market influence,and make the new meaning for "JuSheng dream".

Packaging & Shipping:

![Packaging Packaging]()

![Packaging Packaging]()

Exhibition:

![Exhibition 2024 Exhibition 2024]()

![Exhibition 2023 Exhibition 2023]()

FAQ:

Q:What kind of rock drilling tools can you provide?

A:We have an abundant product portfolio,covering down-the-hole(DTH)hammers and bits.top hammer tools casing systems,and related accessories.

Q:How about your delivery?

A:We have a quick delivery. We have products in warehouse, which enable JuSheng to deliver the goods in a short time.

Q:Do you provide tailored services?

A:JuSheng is working on promoting its own brand and also accepts the advice or suggestions from customers and improve the products. of DTH bits, special requirements on face design, button shapes color logo,and packaging are acceptable.